Samaiden

Commercial Rooftop Solar | Malaysia

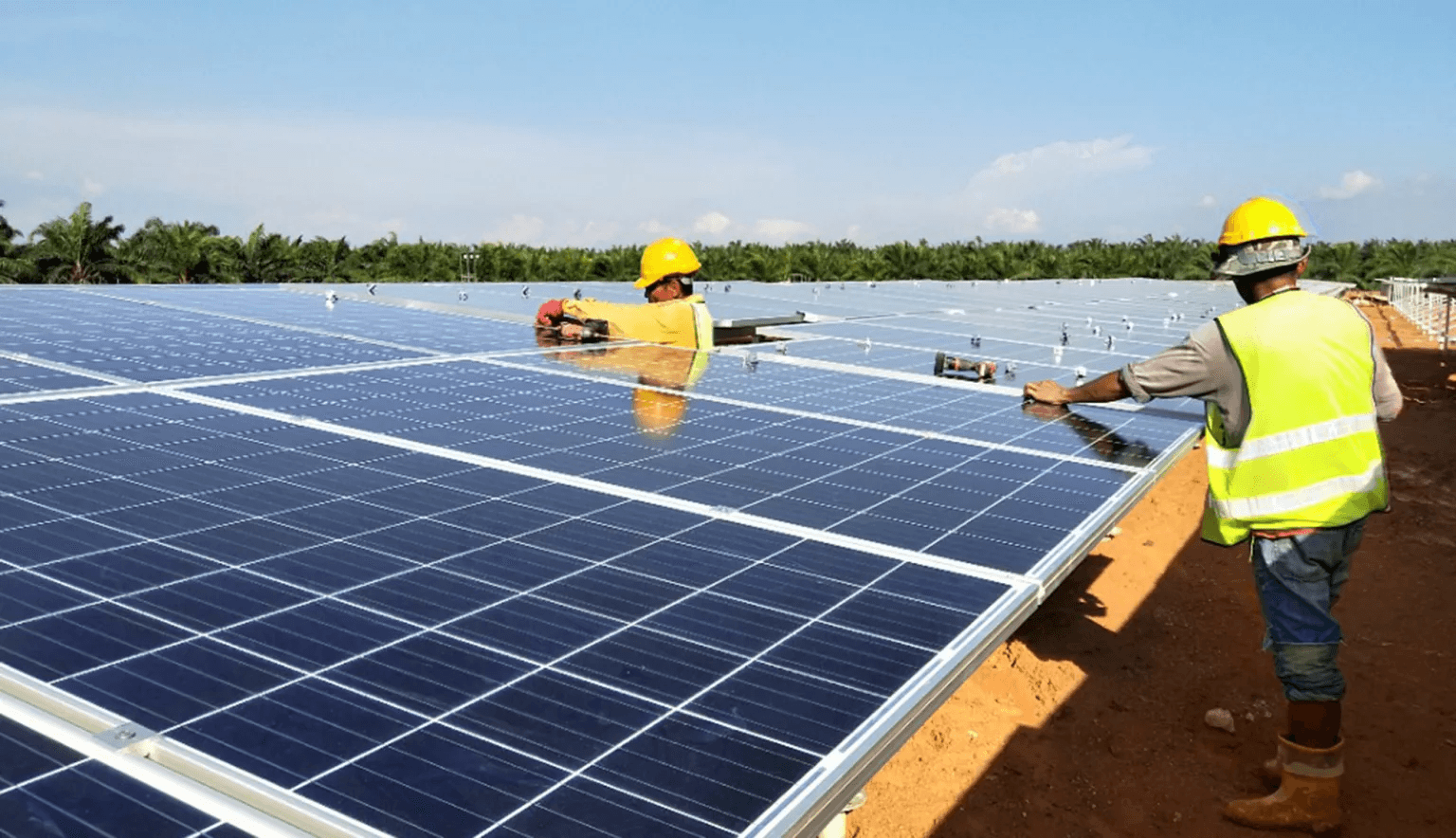

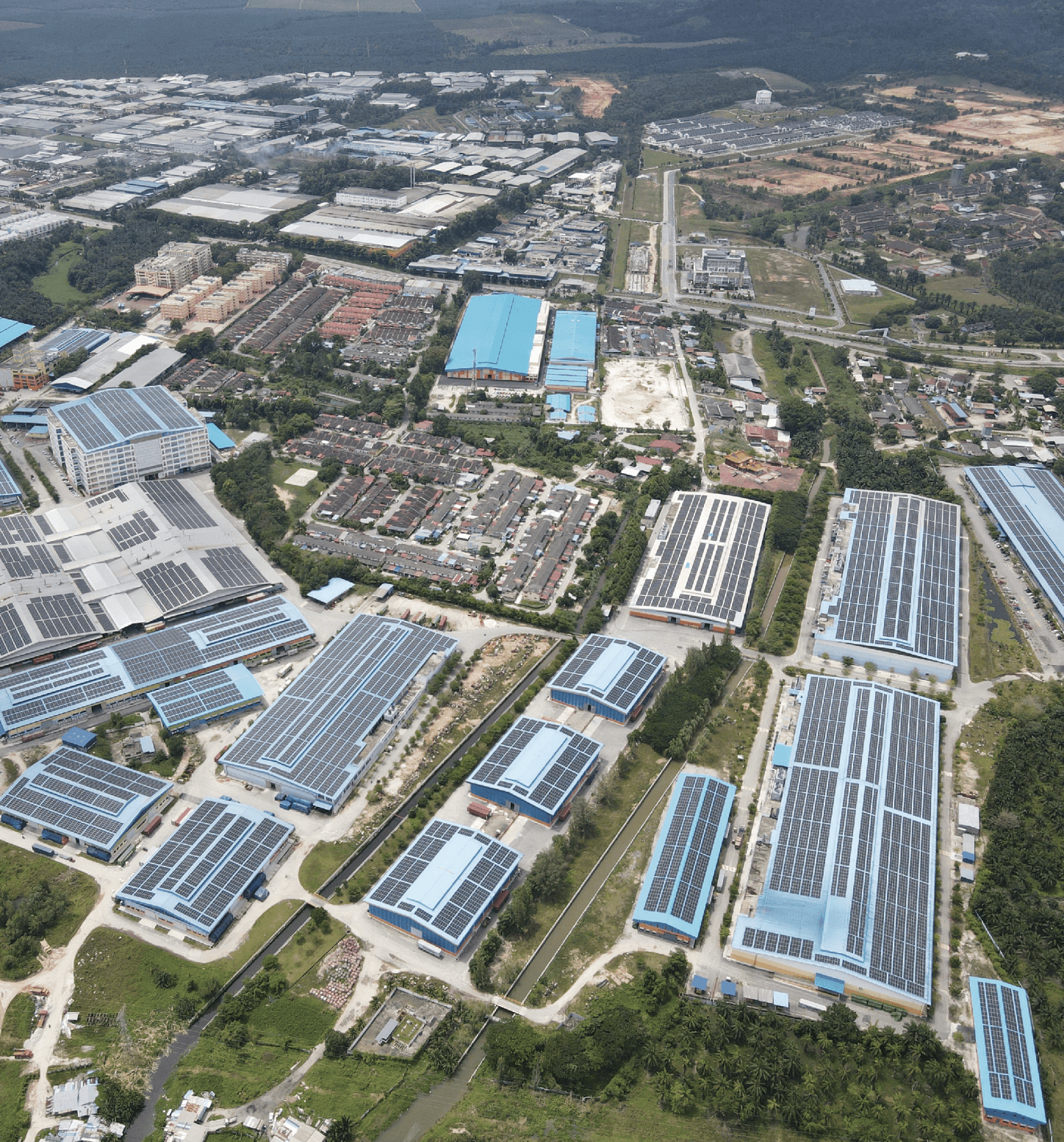

Samaiden Group Berhad, a leading renewable energy company in Malaysia, provides EPC and O&M services for solar projects. In a recent collaboration with global textile manufacturer Ramatex Group, Samaiden developed a 42 MW rooftop solar portfolio across 30 factory buildings, with a total investment of NT$650 million.

Once fully commissioned, the system is expected to generate approximately 52,745 MWh of green electricity annually — equivalent to reducing 33,704 tons of CO₂ emissions in the first year, and over 670,000 tons over 20 years.

Optimizing Complex Power Infrastructure and Connectivity

This self-consumption rooftop solar system spans 30 factory rooftops, integrating 328 inverters and 3,280 strings of solar modules — a highly complex electrical infrastructure. The rooftops are divided into six zones, each with its own design: some follow zero-export (self-consumption only) while others enable partial excess power export.

Given the site is built atop customer-owned factories, establishing reliable connectivity was a challenge. thingnario and Samaiden co-developed a wireless access point solution that enabled on-roof device communication without disrupting factory operations. A master-slave architecture was also implemented to manage cross-rooftop zero-export control and PQIV data integration into TNB’s SCADA system.

With thingnario’s software solution, the EPC team was able to overcome on-site deployment challenges and execute the project more efficiently with reduced workload.

AI-Driven Diagnostics to Enhance O&M

Maintaining solar systems across 30 rooftops is labor-intensive. Manually inspecting every device and string would be time-consuming and inefficient. PHOTON automatically collects and analyzes massive amounts of site data using AI models, detecting anomalies in real time and issuing alerts to help O&M teams quickly locate and resolve disconnections or inverter issues — significantly reducing field troubleshooting time.

thingnario’s platform is purpose-built for multi-rooftop solar systems, enabling group-based event management, intelligent fault categorization, loss estimation, and task prioritization. This allows O&M teams to make smarter decisions and improve overall efficiency.